Welding Line

○ Welding line

The welding process combines parts made with a press.

Spot welding and semiautomatic welding are typical.

For mass production, it is necessary to use jigs and robots.

The order of the welding process is also an important factor.

There are many automatic machines including the inspection process after welding.

One line, one operator is in charge of welding and inspection process.

Therefore, the line configuration by an automatic machine is necessary.

○ Welding provided by MFK

-

Design and manufacture of welding jig

Line remodeling by addition of welding jig

To design and start up the welding process

○Example of welding line

Welding Line with Robot

Install several spot welders and install a robot in the center.

Using robot material handling as a jig, the robot transports parts

Holds the position of parts and feeds it into a spot welder.

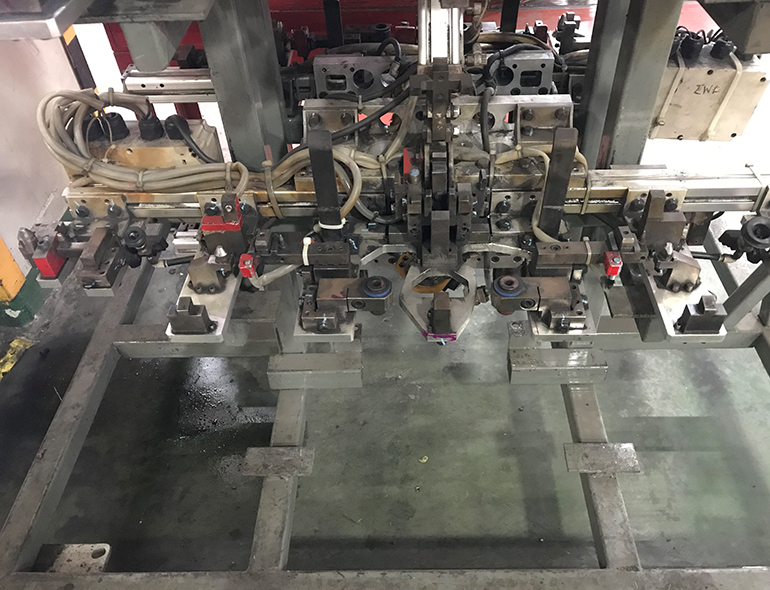

Welding Line with Inspection

Put parts on the rotary table.

Automated operation of material supply, welding, inspection and discharge processes.

The operator takes charge of parts loading.

Automatic discharge after OK, NG judgment.

JIG for Robotic material handling

Material handling design considering robot payload

Parts are pressed products, material handling has adjustment function