Inspection Machine

○ Inspection for mass production

Mass production -Needs the technology to produce the same product every day.

The production line assumes that the same parts always arrive.

As a result, a system that can mass produce the same thing every day is completed.

This technology is very difficult and difficult to continue.

Humans make mistakes, and machines sometimes make mistakes.

There is an inspection process as a way to stop mistakes

-

In the case of inspection process by operator

1,There is a difference in test results between morning and evening.

2,Depending on the physical condition of the day, the test results will differ.

3,Depending on the feeling of the operator, the test results will differ.

I hear it.

○ Inspection machine provided by MFK

-

We propose transportation that does not damage inspection parts.

-

With a simple inspection machine or a fully automatic inspection instrument, it is possible to ensure certainty and reduce tim

-

We recommend using a camera, sensor, laser, etc., an inspection machine that matches the inspection part.

Example of Inspection machine

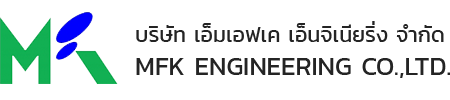

Inspection machine with Robot

Confirmation of existence of many mounted parts Attach the camera to the robot. It can inspect complicated shapes

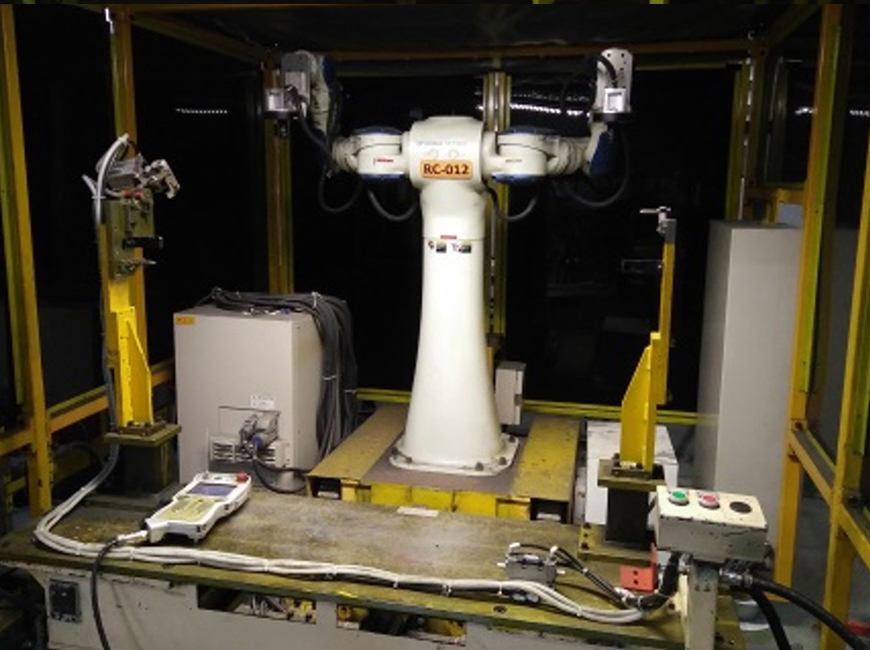

Inspection machine with Camera

Measure the height of cylindrical parts with a linear cylinder

Use a camera to inspect the inside and outside diameter of parts, and scratches on the outer cylinder Use 2 cameras.

A lot of products are put in by parts feeder and inspected by automation.

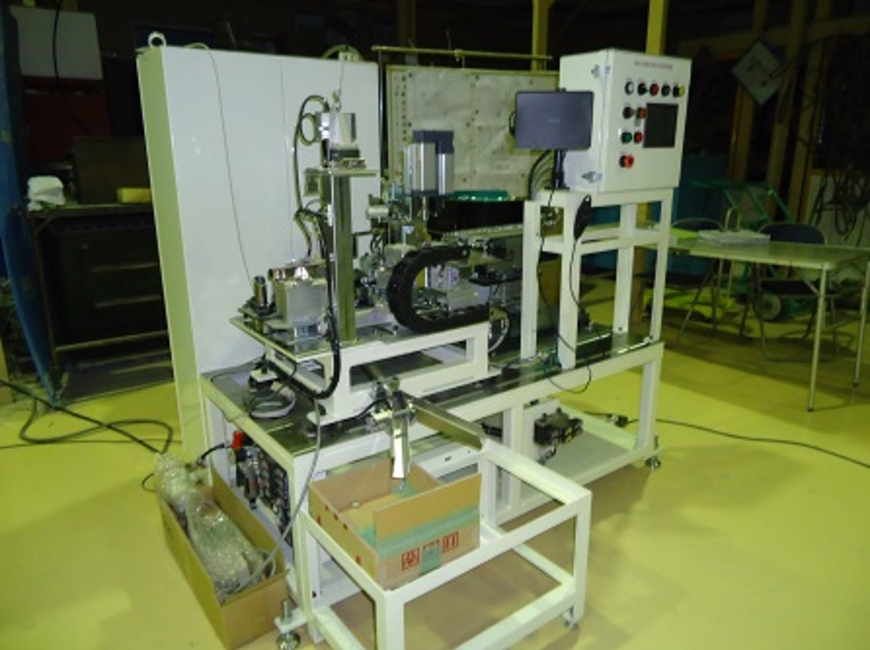

Inspection machine with Displacement sensor

Inspection of bolt shape parallelism

Using 3 sets of touch sensors, calculate the difference and judge pass / fail Parts are transported by air and supplied by the operator.